Product List

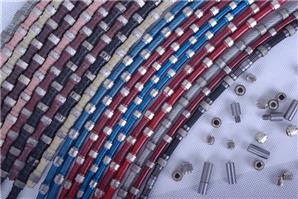

Diamond Wire Saw

Our Vertical Diamond Wire Saws produce smooth, sharp-edged surfaces on virtually any material. The 'cutting tool' is a stainless steel wire with diamonds embedded into the surface of the wire using a patented embedding process, ensures maximum cutting capability and long wire life. The wire is wound onto a drum mounted onto a precision reciprocating motor.

Although it may seem like a contradiction, the Saws produce a non-destructive, non-deforming cut and/or slice. This holds true for both homogeneous materials and for bonded materials of vastly different compositional properties.

Metals, plastics, quartz, glass, graphite and ceramics are just some of the many natural and synthetic materials that can be successfully cut in research and development, quality control, failure analysis and production. The precision cut and resulting smooth finish often eliminate or greatly reduce polishing time for parts that previously required thorough polishing.

Applications

In addition to the industrial applications, these saws are also used within:

1.Metalography

2.Geology

3.Archeology and paleontology

4.Criminology and forensics

5.Biology

6.Pathology

7.Histology

| Technical Information | |

|

Design Cutting Feed Primary Voltage Secondary Voltage Auxiliary voltage Electric motor Primary fuse Secondary fuse WiFi Machine weight without accessories : Overall dimensions Machine control Drum diameter Pulleys diameter CE Certification USB Output Possible wire diameter Wire length Wire speed Wire tension for 0.22 -0.3mm Wire tension for 0.10 -0.17mm Cleaning of wire Max. sample weight Max sample dimension Warranty |

Vertical Gravity (±300g) 230V / 50-60Hz 36Vdc 24Vdc 36V DC - 8A - 200W Ø 5 x 20 - 250 V - 2 A Ø 5 x 20 - 250 V - 10 A Ready, WiFi B/G 13.8kg L x B x H ; 401 x 345 x 455mm Tactil resistive screen 600x480 pixels 83mm 80mm CE 5V / 400mA 0.10 - 0.30mm 10m 0 - 3.6m/s 2kg 1kg With cutting liquid diluted 5% or water 2500g 50 x 50 x 50 mm - Ø 50mm 12 months |

English

English Russian

Russian Spanish

Spanish